[ up

]

A twisted yarn is the result of twisting two or more yarns together.

Why don't you take a thicker yarn instead of twisting two yarns together? This would not cost as much!

|

|

A two-fold twisted yarn has, depending on construction, not only approximately 20 per cent more tensile strength and more extension than the two single yarns together, but even more than the equivalent thicker single yarn. |

|

|

The twisted yarn and the fabrics which have been produced out of it, are more even. |

|

|

The twisted yarn, which is made by a normal twist, is more voluminous, that means, the produced fabrics are better covered. |

|

|

With a twisted yarn a softer and pleasant fabric feel will be obtained. |

|

|

Fabrics made of twisted yarns are more durable and resistant to chaffing. |

|

|

With a twisted yarn a higher dimensional stability of the end-product will be achieved. |

|

|

With special twisted yarns a specific effect and character can be achieved. |

|

|

The twisted yarn has better running characteristics in the subsequent processing and allows a higher efficiency rate. |

|

|

A normal twisted yarn produces less curl than a single yarn (reduction of the inner torque). |

A "normal" twisted yarn (poplin) is made from two single yarns, which are twisted in Z direction. The twisted yarn itself will be twisted in the S direction. The rotation of this twisted yarn is more or less a single yarn twist and the result is, that the fibres will once again lie parallel to the twist axis.

The possibility of variation lies in the amount of the spun fibres as well as in the amount of the twist rotation. The optimum characteristics of the products can be brought out in this way. Stronger twists for weaving mills and softer ones for knitting mills are the general rule.

The sewing thread is normally made of three S-twisted single yarns, which are twisted together in the Z direction.

A tear-resistant thread with a round transverse section will thus be created.

The voile is produced from a spun fibre which is twisted in Z direction. The special thing is, that the twisted yarn is also twisted in the same direction, as the spun fibre (z direction). A hard twisted yarn is the result, with a tendency to curl. The fabric made from it, will be transparent, robust in grip. Curtains were often produced from it years ago. To get a higher transparency and also to produce luminous colours the finished twisted yarn has to be gassed. This means that the fibres which stick out are burnt off.

Very highly twisted yarns are called crêpe twists.

Fancy twists or nub yarns are twisted yarns which are made from different kinds of components such as nub, loop and other effects and are produced on special machines.

Special constructions are multiple and multi stage twisted yarns, which are in praxis of little consequence due to the price factor.

The fineness of cotton yarns can be expressed essentially in three systems.

|

|

metric number Nm |

|

|

English number Ne |

|

|

tex-system |

Nm and Ne are length numbers, this means, the fineness will be defined by the length, the result will be a specific weight.

Nm declares which length weighs 1kg (for example Nm100: 1kg is 100km long).

Ne declares how many times 840 Yards (1 Yard = 0.9144m) makes 1 English pound (0.45359kg) (for example Ne 60: 1 English pound is 60*840=50'400 Yards (=46,08576 km)

The official tex-system, which up to now has not really caught on, is a weight numbering system, this means, the fineness is defined by the weight, which a specific length of the yarn has.

tex means, how many grams does 1 km of a yarn weigh. (for example 10 tex:1 km weight 10 gr).

| Nm | = | 1.69336*Ne Nm | = | 1000/tex |

| Ne | = | 0.590541*Nm Ne | = | 590.541/tex |

| tex | = | 1000/Nm tex | = | 590.541/Ne |

The specification of a twisted yarn can be better illustrated by an example:

Nm 100/2 z1000 / S800 (short cut Nm100/2) |

||

| Nm | = | metric numbering system |

| 100 | = | yarn number of the single yarn (100 km/kg) |

| /2 | = | it is a two-fold twisted yarn (made of two components) |

| z1000 | = | the single yarn is twisted with 1000 rotations per m in z-direction |

| S800 | = | the twisted yarn is twisted with 800 rotations per m in s-direction |

Ne 60/2 z25 / S20 (short cut Ne 60/2) |

||

| Ne | = | English numbering system |

| 60 | = | yarn number of the single yarn |

| /2 | = | it is a two-fold twisted yarn (made of two components) |

| z25 | = | the single yarn is twisted with 25 rotations per inch in z-direction |

| S20 | = | the twisted yarn is twisted with 20 rotations per inch in s-direction |

20 tex z600 x 2 S400 (short cut 20 tex x 2) |

||

| 20tex | = | the tex-system; the number is 20 (20gr/km) |

| z600 | = | the single yarn has been spun with 600 rotations per m in z-direction |

| x2 | = | it is a two-fold twisted yarn |

| S400 | = | the twisted yarn is twisted with 400 rotations per m in s-direction |

The twisting and post treatment takes place in several stages. First two (or more) threads on a doubling bobbin come together.

Doubling

Doubling

This operation can also be made on the twisting machine, where the twisted yarn is very coarse. After that the actual twisting process follows by twisting two (or more) threads together.

Twisting

Twisting

To produce more gloss and to avoid pilling, the fibres, which protrude after the twisting process, can be burnt off.

Gassing

Gassing

Finally you can wind the package to remove the dust, to apply wax or just to get the required package format.

A specialty of the company RUOSS-KISTLER AG is the combination of the doubling and gassing processes. With this combination it is possible to get an almost dust free twisted yarn.

In the area of cotton yarns there are three main types of twisting processes.

|

|

Two-for-one twisting |

|

|

Terrace twisting / Tritec) |

|

|

Ring twisting |

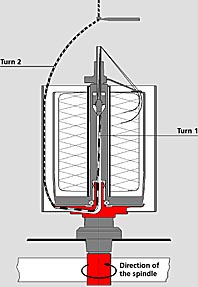

Two-for-one twisting is the most common twisting process in our field. In this process the twisted yarn gets two ply twists with just one spindle turn.

Two-for-one spindle

Two-for-one twisting machine

The process of terrace twisting or tritec is mostly employed in the coarse counts and is used in special areas.

Tritec-Spindle

Tritec-Spindle

The ring twisting process is still only meaningful for nub yarn production. It would be very profitable, but for quality reasons (too many knots in the twisted yarn) hardly used any more.

Had a way been found to replace the knots with a perfect twisting connection (splice), a renaissance of the ring twisting machine would not be impossible.

Nm |

Weaving |

Knitting |

Ne |

Weaving |

Knitting |

|||||

| T/m | T/m | tex | T/i |

T/m |

T/i |

T/m |

tex |

|||

30/2 |

470 |

440 |

33.3 x2 |

20/2 |

12.7 |

500 |

11.7 |

461 |

29.5x2 |

|

40/2 |

540 |

510 |

25.0x2 |

30/2 |

15.6 |

614 |

14.4 |

567 |

19.7x2 |

|

50/2 |

610 |

570 |

20.0x2 |

40/2 |

18.0 |

709 |

16.6 |

654 |

14.8x2 |

|

60/2 |

670 |

620 |

16.7x2 |

50/2 |

20.1 |

791 |

18.6 |

732 |

11.8x2 |

|

70/2 |

720 |

670 |

14.3x2 |

60/2 |

22.0 |

866 |

20.3 |

799 |

9.8x2 |

|

80/2 |

770 |

720 |

12.5x2 |

70/2 |

23.8 |

937 |

21.9 |

862 |

8.4x2 |

|

90/2 |

820 |

760 |

11.1x2 |

80/2 |

25.4 |

1000 |

23.5 |

925 |

7.4x2 |

|

100/2 |

860 |

800 |

10.0x2 |

90/2 |

27.0 |

1063 |

24.9 |

980 |

6.6x2 |

|

110/2 |

900 |

840 |

9.1x2 |

100/2 |

28.4 |

1118 |

26.2 |

1031 |

5.9x2 |

|

120/2 |

940 |

880 |

8.3x2 |

110/2 |

29.8 |

1173 |

27.5 |

1083 |

5.4x2 |

|

130/2 |

980 |

910 |

7.7x2 |

120/2 |

31.1 |

1224 |

28.7 |

1130 |

4.9x2 |

|

140/2 |

1'020 |

950 |

7.1x2 |

130/2 |

32.4 |

1276 |

29.9 |

1177 |

4.5x2 |

|

150/2 |

1'050 |

980 |

6.7x2 |

140/2 |

33.6 |

1323 |

31.0 |

1220 |

4.2x2 |

|

160/2 |

1'090 |

1'010 |

6.3x2 |

150/2 |

34.8 |

1370 |

32.1 |

1264 |

3.9x2 |

|

170/2 |

1'120 |

1'040 |

5.9x2 |

160/2 |

36.0 |

1417 |

33.2 |

1307 |

3.7x2 |

|

180/2 |

1'150 |

1'070 |

5.6x2 |

170/2 |

37.1 |

1461 |

34.2 |

1346 |

3.5x2 |

|

190/2 |

1'190 |

1'100 |

5.3x2 |

180/2 |

38.1 |

1500 |

35.2 |

1386 |

3.3x2 |

|

200/2 |

1'220 |

1'130 |

5.0x2 |

|||||||

210/2 |

1'250 |

1'160 |

4.8x2 |

|||||||

220/2 |

1'280 |

1'190 |

4.5x2 |

|||||||

230/2 |

1'300 |

1'210 |

4.3x2 |

|||||||

240/2 |

1'330 |

1'240 |

4.2x2 |

|||||||

250/2 |

1'360 |

1'260 |

4.0x2 |

|||||||

260/2 |

1'390 |

1'290 |

3.8x2 |

|||||||

270/2 |

1'410 |

1'310 |

3.7x2 |

|||||||

280/2 |

1'440 |

1'340 |

3.6x2 |

|||||||

290/2 |

1'460 |

1'360 |

3.4x2 |

|||||||

300/2 |

1'490 |

1'390 |

3.3x2 |

|||||||

The twist of a doubled yarn depends on the twist number. The rotation coefficient (alfa) determines the hardness of a twisted yarn.

The formula for the corresponding numbering-system:

|

Nm |

Ne |

|

alfa m = T / Nm½ |

alfa e = T / Ne½ |

T = twist rotation per m |

T = twist rotation per m |

T = twist rotation per inch |

Examples of rotation coefficient:

| soft | medium | hard | |

| alfa tex | 3100 | 3800 | 5700 |

| alfa m | 100 | 125 | 180 |

| alfa e | 3.25 | 4 | 6 |

Conversion:

alfa tex = alfa m * 31.6

alfa tex = alfa e * 957

alfa m = alfa e * 30.3

Copyright © 2005 state: 17. April 2011